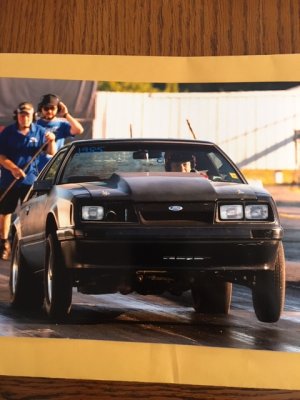

black88coupe

Club Member

Took my car out yesterday. My goal this year is to focus on getting my chassis to work better and be consistent. My latest project has been to get 10lbs. or more off the nose. Sounds simple but I'm looking in places that a lot of people wouldn’t consider. The easy stuff is done like a tubular K/ manual rack/ etc. Been lightening stuff up to get the car more balanced front to rear. So far I’ve lost 10lbs. off the nose with more ideas to shed weight. These are all things that only cost my time- not money.The best 60’ so far was a 1.59- lifting the left front wheel. Last night it picked up both wheels and had a 1.65 60’. So, The car was leaving softer but working better. It’s the little things in low powered cars like mine that make the difference. Just keep chipping away at it.