Copied from IHRA rulebook.........

General roll bar specs

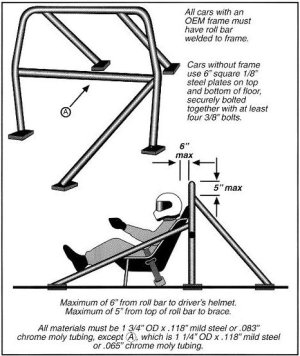

ROLL BARS: All roll bars must be within 6” of the rear, or side, of the driver’s head,

extend in height at least 3” above the driver’s helmet with the driver in normal driving

position, and at least as wide as the driver’s shoulders or within 1” of the driver’s door.

Must be adequately supported or cross-braced to prevent forward or lateral collapse.

Braces must be of the same diameter and wall thickness as the roll bar and intersect

with the roll bar at a point not more than 5” from the top of the roll bar. Side-bar must

be included on driver’s side. The side bar must pass the driver at a point midway

between the shoulder and elbow.

All vehicles with OEM frame must have roll bar welded to frame; installation of frame

connectors on unibody cars does not constitute a frame and, therefore, it is not

necessary to have the roll bar welded to the frame. Cars without frame must securely

attach roll bar with 6” x 6” x .125 steel plates on top and bottom of floor bolted together

with at least four 3/8” bolts and nuts. If roll bar is welded to the rocker sill area with

.125” reinforcing plates, the 4 attachment bolts are not mandatory. All chrome moly

welding must be done by approved TIG Heliarc process; mild steel welding may be done

by MIG (wire feed) or TIG process.Welding must be free of sag and porosity. Any grinding

of welds prohibited. See following illustration. Roll bar must be padded any where

driver’s helmet may contact it while in driving position. Adequate padding must have minimum 1/4” compression.

ROLL CAGE: All cage structures must be designed in an attempt to protect the driver

from any angle, 360-degrees; cars with out inspection above driver’s legs must have a

shield or device to prevent legs from protruding outside chassis. When driver is in driving

position in an open bodied car, roll cage must be at least 3” in front of helmet. On front

engine dragster, seat uprights and back braces must be arranged such that a flat

surface passed over any two adjacent members will not contact the driver seat or

containment. Additional uprights, max 30 degrees from vertical, must be added until this

criteria is satisfied.

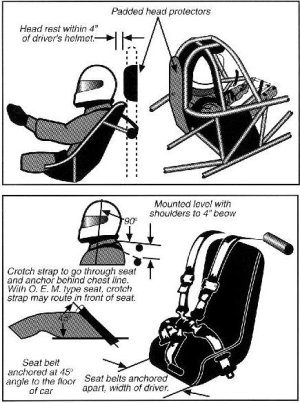

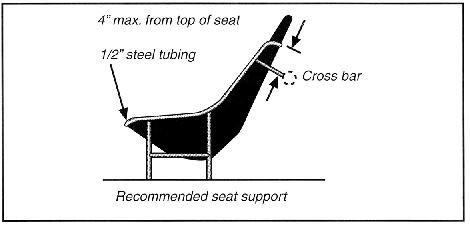

On full bodied car, with driver in driving position, helmet must be in front of main hoop.

Side bar must pass the driver at a point midway between the shoulder and elbow. All

cage structures must have in their construction a cross bar for seat bracing and as the

shoulder harness attachment point; cross bar must be installed no more than 4” below,

and not above, the driver’s shoulders or to side brace. On any car where the stock

flooring has been removed, the roll cage must incorporate a rocker or sill bar to tie the

front and rear of the roll cage together. Minimum specifications: 1-5/8”OD-.083cm, or

1-5/8”OD.118ms or 2”x2”x.058 box tubing. Mild steel welding may be done by MIG or

TIG process. All chromoly must employ only TIG process. Welding must be free of slag

and porosity. Any grinding of welds prohibited. See FRAMES for chassis certification

procedures. See following illustrations, Roll cage. Additionally, roll cage must be padded

any where the driver’s helmet may contact it while in the driving position.

Swing out bars are permitted on OEM full bodied entries running 8.50 and slower. They must

be designed as follows: 1 5/8 diameter x .083 cm or .118 ms connected with a minimum

of 3/8 bolts or pins affixed in double shear. Clevis or sliding sleeve connections permitted.

All male brackets must be a minimum of 1/8 inch with corresponding female bracket being

1/4 inch. Sliding sleeves must have a minimum of 2 inch engagement at the connection.

Chrome plating of roll cage prohibited on all entries running 7.50 or quicker 1/4 mile, or

on entries that want a certification that is within that respective SFI specs E.T. range. A

dash bar and rocker sill bar are mandatory on all entries running 150 mph or quicker or

if the OEM firewall has been modified in excess of 1 square foot for transmission

removal. Minimum specifications: 1-1/4” x .058cm, or 1-1/4” x .118ms.

Head guards or helmet bars must be installed on all entries presented for certification

under SFI specifications 2.2B, 2.3K, 2.4, 2.5A, 2.6, 2.7A, and 10.1E. The minimum

specification is 1 inch X .058 cm. See appropriate SFI specification for all full bodied entries

8.49 or quicker 1/4 mile. Chassis certifications are mandatory on all entries running 9.00

or quicker 1/4 mile, or 6.00 or quicker 1/8 mile or on any vehicle that exceeds 150 mph.

What you have to keep in mind is that what is going to govern the height of the bar is where your seat and harness mounts are.

Good luck.

--Joe